The MajorDomus® system is a large and professional tool with the task of full control over technical devices (in particular for security purposes) both automatically and supporting the work of persons responsible for safety and “maintenance”. It can control unlimited number of devices, and more importantly it does not have to be planned and built from the beginning as a “big” management system (where you need to design and define a whole lot of dependencies and work patterns), but it can be implemented “step by step”. This gives the investor:

- Time to define dependencies in accordance with the practical requirements of the object,

- The ability to avoid huge costs associated with the implementation and training of personnel,

- Time to adapt the facility users to new working conditions,

- The possibility of financing the entire project in a way that does not burden the company’s budget beyond the possibilities thanks to:

- Possibilities of “mixing” different subsystems (access control, panic, lighting etc. on one communication bus – common practice). In the case of simple, small systems, all subsystems can and most often work on a common communication bus. This fact in no way diminishes the capabilities of the system, does not reduce the speed of work, does not affect the work of subsystems and cooperation between them. In the case of complex systems, each subsystem can be built based on a single bus (or in the case of extremely complex installations, on a separate computer), but this is in order to obtain greater transparency and proper organization of the system,

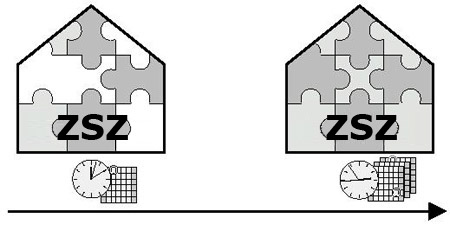

- Possibility to install any controllers as needed. Due to the modular design of the system, there are no restrictions in its expansion (you should only remember to limit the number of controllers that can be connected to one computer). The system construction cycle can last any period of time and be closely tailored to the needs or financial capabilities of the user. If it is necessary to add a single controller in the system, the entire procedure is limited to assigning an address in the system, connecting it to the communication bus, defining its tasks and, in the case of input / output controllers, connect external devices. A similar procedure applies when adding more controllers (e.g. securing the next floor, building, etc.). It is enough to connect the controllers with a communication bus to a computer, define their tasks, attach external devices and the whole system without any interference in the previous configuration will start working,

- Stand alone installation or under the supervision of the Meco System. The program comes with a description on the CD-ROM. It has been equipped with a hint system that “guides” the user through subsequent stages of the installation. The process of setting up and then booting the system is described step by step in details in the program’s instruction. The whole programming procedure consists of performing the following described activities. They are so intuitive that even an untrained user can easily configure and then start using the system. In the event of difficulties for the user to achieve the intended effect or the need for additional consultation during installation or configuration of the system, the company’s specialists are at the client’s disposal. Support can be provided over the phone as well as in the form of direct supervision at the client’s place,

- Self-training of installation employees due to the fact that the user works with the system at all stages of its creation, from the moment of installation, through the procedures of defining the system, to operating the system in everyday use, thoroughly and precisely learns the entire system and learns to solve emerging problems in practice . Such experiences are extremely useful when the system is enlarged and it is necessary to program it,

- Adding existing and independently operating systems or individual devices to the created IMS at any stage of its creation. The integration of IMS with the systems installed at the customer depends on the existing state. The system is able to interpret events from external systems if they have the form of a change in logic states. Connecting such an event to the input port of the controller and assigning it a mnemonic name gives a clear picture of the work of this system. A similar situation occurs when it is necessary to control specialized devices already installed at the customer’s site. Generally there are no restrictions here. Thanks to the possibility of building IMS in stages, it is not necessary to purchase all the system components at once, and thus to incur significant cost. The whole process can take any time, the pace of work can be closely adjusted to the work schedule of the assembly teams or the financial capabilities of the investor. By building the system in this way we have full control over the costs incurred and the equipment is not “lying” not used in the warehouse.